How a Dry Cooler Manufacturer Utilizes Conduction in Thermal Management

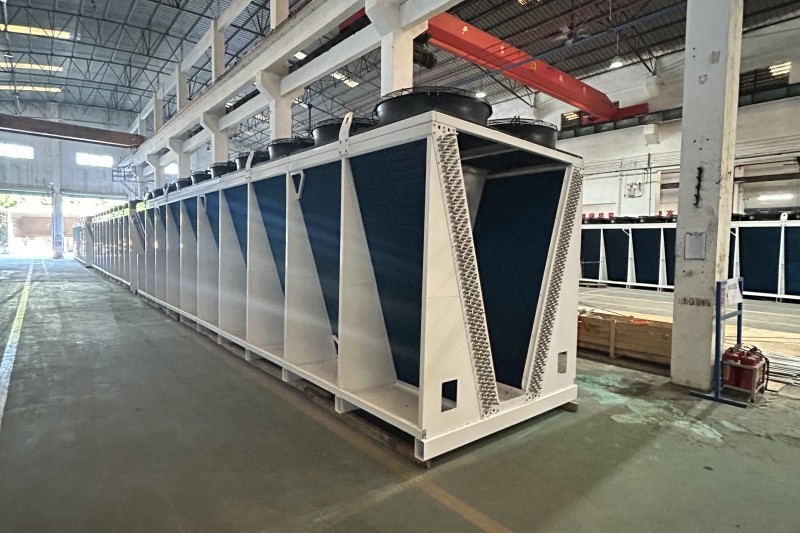

As a premier dry cooler manufacturer, we at Boyi Cooling understand that efficient thermal management is the backbone of numerous industrial applications. At the core of industrial cooling technology, dry coolers expertly utilize the fundamental principle of heat conduction to manage and dissipate thermal energy. This post will explore how we, as specialists in the field, harness conduction to achieve superior thermal management.

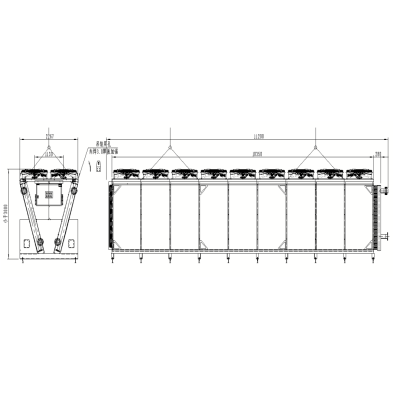

Dry coolers are indispensable in modern industrial settings, offering a method to cool process fluids without the need for water evaporation. This characteristic makes them a particularly sustainable and cost-effective choice, especially in areas where water is scarce or of poor quality. The performance of a dry cooler is fundamentally tied to the effective conduction of heat through its essential components. The entire process is a continuous cycle designed to maintain optimal operating temperatures for industrial processes.

Key Takeaways

Conduction is the primary mechanism for heat transfer in a dry cooler, moving thermal energy from the internal fluid to the outer surfaces. The process starts with heat conducting through the fluid to the pipe walls, then through the pipe material itself, across the bond to the fins, and finally along the fins. The efficiency of this pathway is dictated by the materials used, with high-conductivity metals like copper and aluminum being preferred. The design, including fin geometry and the quality of the bond between tubes and fins, is critical in minimizing thermal resistance and maximizing the surface area for heat dissipation.

The Role of Conduction in Boyi Cooling's Dry Cooler Design

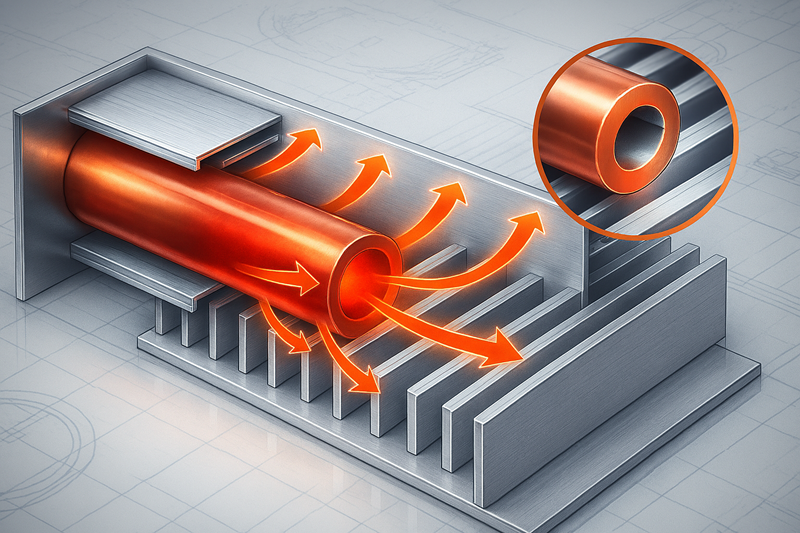

The operational principle of a dry cooler revolves around the effective transfer of heat through both conduction and convection. A hot process fluid, often a water-glycol mixture, circulates through the cooler's coils. As this fluid moves, heat is transferred by conduction from the fluid to the inner walls of the coils. This thermal energy then continues its journey, conducting through the solid material of the coils to the outer surface. From there, convection takes over as fans generate airflow across the coils, carrying the heat away into the ambient air. It is this seamless pathway, dominated by conduction, that dictates the cooler's overall efficiency. At Boyi Cooling, every aspect of our design is optimized to perfect this conductive heat transfer process.

Fin and Tube Heat Exchangers: The Heart of the System

At the heart of every dry cooler is the fin-and-tube heat exchanger. This component is where the critical heat transfer occurs, and its design is paramount to the cooler's performance. The fin-and-tube system is engineered to facilitate a highly efficient conductive pathway from the hot fluid inside the tubes to the ambient air outside.

Pipes and Heat Transfer

The journey of heat dissipation begins inside the pipes. The hot fluid flowing within transfers its thermal energy to the interior surface of the pipe wall. The first step in this process is conduction through the pipe's material. The efficiency of this step depends on the pipe's thermal conductivity and its wall thickness. A material with high conductivity allows heat to move through it with minimal resistance. The heat then travels from the inner wall to the outer wall of the pipe, ready to be transferred to the next stage of the system: the fins.

Fins for Maximized Surface Area

Once heat has conducted through the pipe wall, it must be dissipated into the surrounding air. However, the surface area of the pipes alone is insufficient for rapid cooling in most industrial applications. This is where fins play a crucial role. Fins are thin sheets of metal attached to the exterior of the pipes, designed to dramatically increase the available surface area for heat exchange.

Heat conducts from the outer surface of the pipe directly into the base of the fins. From there, it travels along the length of the fins, spreading out across a much larger area before being transferred to the air via convection. The effectiveness of the fins is directly related to their material, thickness, and geometry, all of which are carefully selected to ensure an uninterrupted and efficient conductive path.

Material Selection by Boyi Cooling for Optimal Conductivity

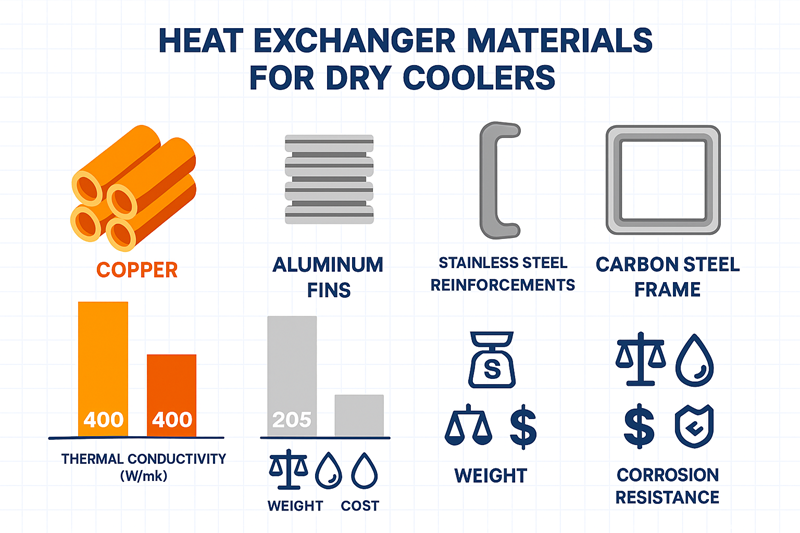

The choice of materials is a critical decision for dry cooler manufacturers as it directly impacts the efficiency and durability of the heat exchanger. The primary goal is to select materials that offer the highest possible thermal conductivity while also providing corrosion resistance and structural strength.

High Thermal Conductivity Materials

To maximize the rate of heat conduction, materials with high thermal conductivity are essential. Metals like copper and aluminum are the most common choices for this reason. Copper, in particular, has exceptional thermal conductivity due to its atomic structure, which allows for the rapid transfer of thermal energy. Aluminum is also an excellent conductor and offers the additional benefits of being lightweight and highly resistant to corrosion, making it ideal for the fins. While materials with superior conductivity can sometimes be more expensive, their impact on operational efficiency often leads to long-term cost savings.

Here is a comparison of common materials used in heat exchangers:

| Material | Key Properties | Common Application in Dry Coolers |

|---|---|---|

| Copper | Excellent thermal conductivity, good corrosion resistance. | Tubes |

| Aluminum | High thermal conductivity, lightweight, cost-effective. | Fins |

| Stainless Steel | High strength, excellent corrosion and temperature resistance. | Tubes in corrosive environments |

| Carbon Steel | Cost-effective, good conductivity. | Structural components, or tubes with protective coatings |

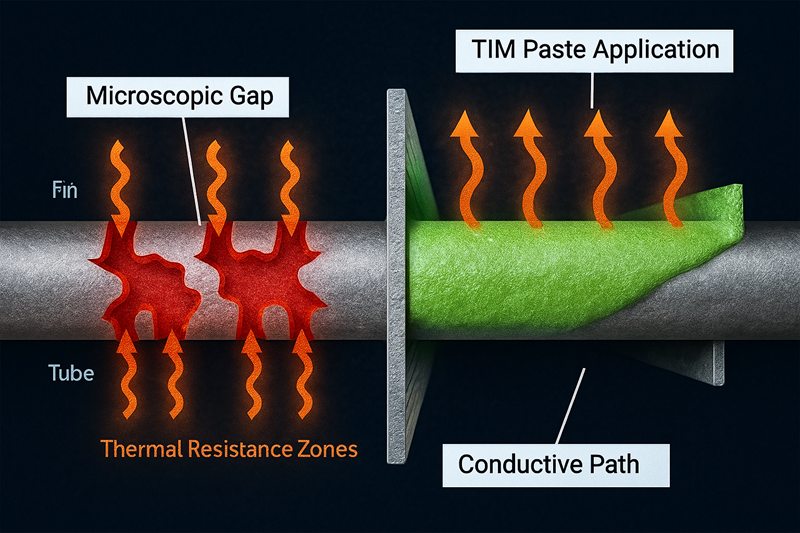

Ensuring Quality Bonding

The most conductive materials will be rendered ineffective if the connection between them creates a thermal barrier. Even microscopic air gaps between the pipe and the fin can create significant thermal resistance, severely impeding heat flow. Therefore, the method used to bond the fins to the tubes is critical for ensuring seamless conduction.

At Boyi Cooling, we utilize advanced bonding techniques to create a perfect, continuous metal-to-metal contact. Methods such as mechanical expansion, where tubes are expanded to fit tightly into the fin collars, or brazing, which uses a filler metal to fuse the components, ensure that there are no gaps. This creates a robust, integral bond that maximizes thermal performance and guarantees the structural integrity of the fin-tube assembly, preventing issues like thermal degradation from constant expansion and contraction. The lack of proper contact is a known parameter that interferes with the heat transfer in a fin-tube heat exchanger.

Optimizing Conduction for Enhanced Performance in Boyi Cooling's Dry Coolers

Achieving good thermal conductivity is only the starting point. To truly excel, every element of the dry cooler's design must be refined to create the most efficient path for heat transfer. At Boyi Cooling, we focus on innovative engineering and precision manufacturing to optimize conduction, ensuring our dry coolers deliver exceptional performance. This involves a deep dive into the geometry of the fins, the dimensions of the tubes, and the use of specialized materials to bridge any potential gaps in the conductive pathway.

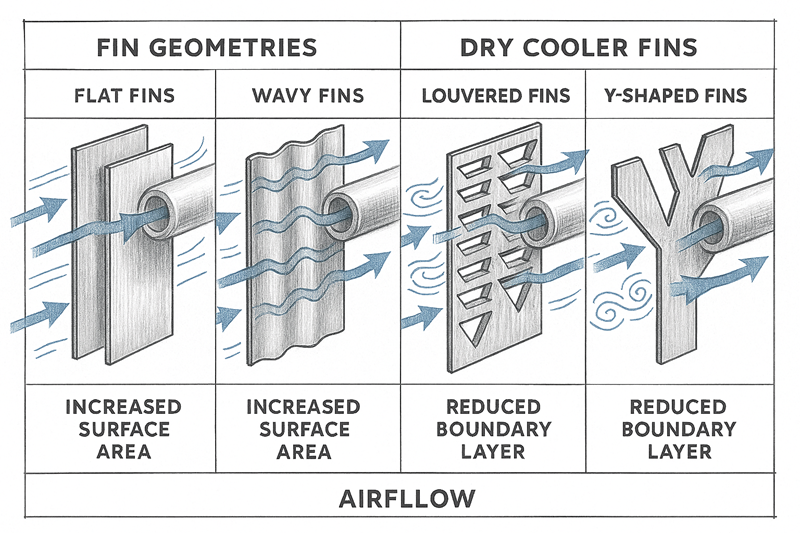

Innovative Fin Geometry and Design

The shape of the fin has a significant impact on both heat transfer and air-side pressure drop. While a simple flat fin is effective, advancements in design have led to far superior performance. At Boyi Cooling, we have moved beyond traditional designs to implement more complex and effective geometries.

Innovations like wavy, corrugated, or louvered fins are used to enhance performance. These designs disrupt the air's boundary layer as it flows over the fin, creating turbulence that promotes better mixing of air and increases the heat transfer coefficient. Some advanced designs, such as disk fins or Y-shaped fins, can be even more effective by directing airflow purposefully toward the heat source (the tubes). These novel shapes are designed to reduce thermal resistance without a significant increase in the energy required to move the air (pumping power). By optimizing the shape, angle, and arrangement of these features, we can maximize heat rejection while maintaining energy efficiency.

Precision in Tube Diameter and Wall Thickness

The dimensions of the tubes are another critical variable in optimizing conduction. There is a delicate balance to strike between thermal performance, pressure drop, and structural integrity.

-

Tube Diameter: Smaller diameter tubes generally offer better heat transfer performance. This is because a smaller diameter increases the fluid velocity for a given flow rate, which can lead to a higher convective heat transfer coefficient inside the tube. Additionally, it increases the surface-area-to-volume ratio. However, a smaller diameter also increases the pressure drop, which requires more pumping power. The choice of diameter is therefore a trade-off based on the specific application and desired operational efficiency.

-

Wall Thickness: The tube wall itself presents a conductive thermal resistance. A thinner wall reduces this resistance, allowing heat to pass through more quickly. However, the wall must be thick enough to withstand the pressure of the fluid inside and provide long-term durability. Thicker walls can increase thermal resistance, potentially hindering the conductive heat transfer from the fluid to the fins. Our engineers carefully calculate the optimal wall thickness using high-strength materials that allow for minimal thickness without compromising safety or longevity.

The Strategic Use of Thermal Interface Materials by a Dry Cooler Manufacturer

Even with the most precisely manufactured components, microscopic imperfections on the surfaces of the tubes and fins can create tiny air gaps. Since air is a very poor thermal conductor, these gaps act as insulation, hindering heat flow and reducing the overall efficiency of the cooler.

To overcome this, we strategically use Thermal Interface Materials (TIMs). A TIM is a substance applied between two surfaces to fill these air gaps and ensure a continuous, highly conductive path. TIMs come in various forms, including thermally conductive greases, pastes, pads, or adhesives. By filling any potential voids between the tube and the fin collar, TIMs drastically reduce the contact thermal resistance. This ensures that the heat conducted from the tube can flow seamlessly into the fin, maximizing the effectiveness of the entire heat exchange surface. The application of TIMs is a mark of a high-quality manufacturing process and is crucial for achieving peak thermal performance and reliability.

Boyi Cooling's Commitment to Efficient Dry Cooler Solutions

As a specialized dry cooler manufacturer, Boyi Cooling is committed to not only mastering the principles of thermal conduction but also applying them to solve real-world industrial challenges. Our focus extends beyond building efficient hardware; we aim to deliver holistic solutions that are both powerful and responsible, emphasizing sustainability and long-term value for our clients.

Addressing Industrial Cooling Challenges

Industrial environments present a host of cooling challenges that demand robust and adaptable solutions. These can range from extreme ambient temperatures that reduce a cooler's effectiveness to significant space constraints and corrosive atmospheric conditions.

- High Ambient Temperatures: One of the main challenges for air-cooled systems is a drop in performance on hot days. Our designs compensate for this with optimized fin density and high-efficiency fans, ensuring reliable performance even in challenging climates. For extreme conditions, we can integrate adiabatic systems that pre-cool the intake air, boosting performance when it's needed most.

- Space Constraints: In many industrial facilities, space is a premium. We design compact dry coolers that offer a high cooling capacity within a minimal footprint. This is achieved through advanced fin designs and optimized component layouts that maximize heat transfer surface area without increasing the overall size of the unit.

- Corrosive Environments: Industrial sites can expose equipment to corrosive elements. Material selection is critical here. By using materials like stainless steel or applying specialized coatings to aluminum and copper components, we ensure the longevity and sustained performance of our coolers, preventing degradation that would otherwise impede thermal conduction.

Sustainability and Energy Efficiency in Dry Cooling

In today's world, sustainability isn't just a bonus—it's a core requirement. Dry cooling technology is inherently sustainable, and we are dedicated to maximizing its environmental benefits.

- Water Conservation: The most significant sustainability advantage of dry coolers is that they consume no water for cooling. Unlike cooling towers that lose large amounts of water to evaporation, dry coolers use a closed-loop system, making them the ideal solution for arid regions or any facility focused on reducing its water footprint. This can result in water savings of up to 95% compared to traditional wet cooling systems.

- Energy Efficiency: Efficient conduction directly translates to energy savings. A well-designed dry cooler that transfers heat effectively requires less fan power to achieve the desired cooling. We further enhance this by using high-efficiency motors and variable speed drives (VFDs) on fans and pumps. These intelligent controls allow the cooler to adapt to varying thermal loads and ambient conditions, consuming only the energy that is necessary and significantly reducing operational costs.

- Reduced Environmental Impact: By eliminating water consumption, dry coolers also eliminate the need for chemical water treatments like biocides and corrosion inhibitors, which can be harmful to the environment. This chemical-free operation, combined with lower energy consumption, results in a significantly smaller carbon footprint and a cleaner, more responsible cooling solution.

Frequently Asked Questions (FAQs)

1. What is the fundamental principle behind a dry cooler? A dry cooler operates on the principles of heat conduction and convection. A hot fluid circulates through a series of tubes, and heat is conducted through the tube walls to attached fins. Fans then blow ambient air across these fins, and the heat is transferred to the air via convection, cooling the fluid inside.

2. Why is conduction so important in a dry cooler? Conduction is the critical process that moves heat from the internal fluid to the outer surfaces where it can be dissipated. The efficiency of conduction through the tubes and fins determines the overall performance of the cooler. Poor conduction creates thermal resistance, which acts as a barrier to heat transfer and reduces efficiency.

3. What materials are best for promoting conduction in a dry cooler? Materials with high thermal conductivity are essential. Copper and aluminum are the most widely used materials because they allow heat to travel through them with very little resistance. Copper is often used for the tubes due to its excellent conductivity, while lightweight and corrosion-resistant aluminum is typically used for the fins.

4. How do you ensure a good conductive bond between the tubes and fins? A tight, seamless bond is crucial. We use methods like mechanical expansion, where the tubes are physically expanded to lock into the fins, or brazing, which fuses the parts together. These techniques eliminate insulating air gaps to ensure an uninterrupted path for heat conduction. Poor contact significantly increases thermal resistance.

At Boyi Cooling, our dedication to perfecting conduction in our dry cooler products ensures that our clients receive high-performance, durable, and environmentally responsible thermal management solutions. By continuously innovating in design, material selection, and manufacturing processes, we, as a dedicated dry cooler manufacturer, remain at the forefront of providing efficient and reliable dry cooling technology for a wide range of industrial applications. We encourage you to explore how our advanced solutions can benefit your operations.