Material Prepare

- Tube Type:

- Copper, Stainless Steel.

- Tube Size:

- Ø7, Ø9.52, Ø12.7, Ø15.88. Copper tube open material size, positive and negative tolerances should be in line with GBT1804-C level.

Can process various thicknesses of stainless steel, aluminum, galvanized sheet and other various plates.

Thread the copper or stainless steel tube into the end plate in the direction of the flap holes according to the coil drawing and the corresponding tube connection method drawing.

Ensure that the internal and external surfaces of the pipe are clean, and there shall be no oxidized film, copper chips, oil spots, etc. The pipe shall be of uniform texture, and there shall be no defects affecting the use, such as cracks, abrasions, skinning, slagging, rough pulling paths and pits.

Before delivery, Quality inspection of the product inspection qualified, affixed with a qualified label before shipment.

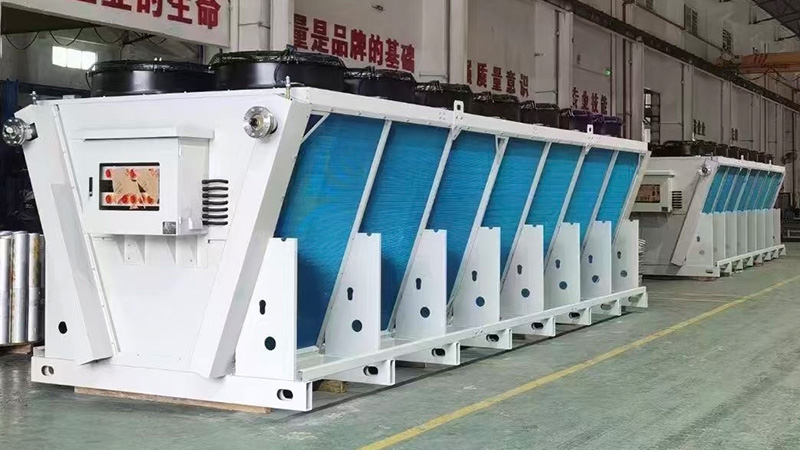

Our Experts Can Provide One-stop Data Center Cooling Solutions for Your Project