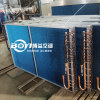

Innovative Commercial and Industrial Heat Transfer Solution Providers

Custom evaporator in cold air fan

| Categories | Evaporator Coils |

|---|---|

| Brand | Boyi Heat Transfer Industry Support Customization |

| Model | BY-ZFQ |

| Core Component | Finned tube heat exchangers |

| Tube Diameter | 7mm, 9.52mm, 12.7mm, 15.88mm |

| Casing Material | Galvanized Steel, Aluminium, Stainless Steel |

| Tube Material | copper, stainless steel |

| Fin Material | aluminum, copper, stainless steel |

| FOB port | guangzhou |

| Terms of Payment | L/C, D/P, Western Union, MoneyGram, T/T, Paypal |

| Update Time | Jul 2,2025 |

Detail Information

Custom evaporator in cold air fan

In a chiller, the main function of the evaporator is:

1. Heat absorption and cooling: Liquid refrigerant evaporates into gaseous state in the evaporator and absorbs heat from the surrounding air, thus reducing the air temperature.

2. Air dehumidification (some models): when the air contacts the low-temperature evaporator surface, the moisture may condense and precipitate out, realizing a certain degree of dehumidification (but the dehumidification effect of the direct-expansion evaporative chiller is weak).

Workflow of evaporator in chillers

1. Refrigerant cycle:

1.1 The compressor sends the high-temperature, high-pressure gaseous refrigerant into the condenser, where it cools down and becomes a high-pressure liquid.

1.2 The liquid refrigerant enters the evaporator after depressurization through the expansion valve, and evaporates and absorbs heat at low pressure.

1.3 The heat-absorbed low-temperature, low-pressure gaseous refrigerant returns to the compressor, completing the cycle.

2. Air cooling:

2.1 The fan draws hot air into the chiller, which flows over the surface of the finned tubes of the evaporator.

2.2 The refrigerant evaporates inside the tube and absorbs heat from the air outside the tube, causing the air temperature to drop significantly.

2.3 The cooled air is blown out by a fan to achieve environmental cooling.

Structural characteristics of the evaporator

The evaporator in a chiller is usually designed to:

A. Finned tube structure: copper tube sets aluminum fins, increasing the heat exchange area and improving efficiency.

B. Multi-row pipe design: Enhance the heat exchange capacity and adapt to the demand of large air volume.

C. Anti-corrosion treatment: Because of the possibility of contact with humid air, the surface is often treated with a hydrophilic coating or anti-corrosion treatment.

Strengths and limitations

1. Strengths:

1.1 High energy efficiency: The energy efficiency ratio (COP) of the evaporative heat absorption principle is significantly higher than that of conventional compression refrigeration.

1.2 Environmentally friendly: Some models use water as a medium and are Freon-free.

2. Limitations:

2.1 Dependent on ambient humidity: cooling effect decreases in high humidity environments.

2.2 Maintenance required: The evaporator is easy to accumulate dust or scale, and needs to be cleaned regularly.

Application Scenarios

Evaporator chillers are widely used:

A. Industrial cooling: workshops, warehouses, greenhouses and other large spaces.

B. Commercial locations: shopping malls, restaurants, data centers.

C. Domestic: Portable chillers or window air conditioners.

Maintenance Points

1. Clean fins: Prevent dust clogging from affecting heat exchange.

2. Check refrigerant: leaks can cause a loss of efficiency.

3. Drainage system: avoids condensation buildup that breeds bacteria.

- Specifications can be tailored to suit each application, with different materials, sizes, noises and cooling mediums available.

- contact us

Review

- Loading...

Please send your message to us

- Tel

- *Title

- *Content