Innovative Commercial and Industrial Heat Transfer Solution Providers

Home / All / Evaporator Coils / Custom Different Size Evaporator Coil with Copper Tubes Aluminum Fin

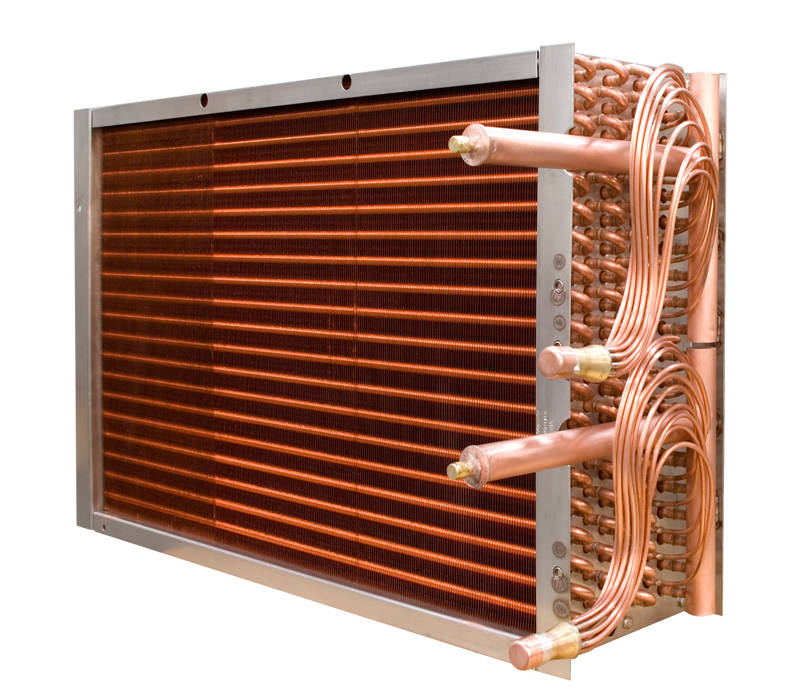

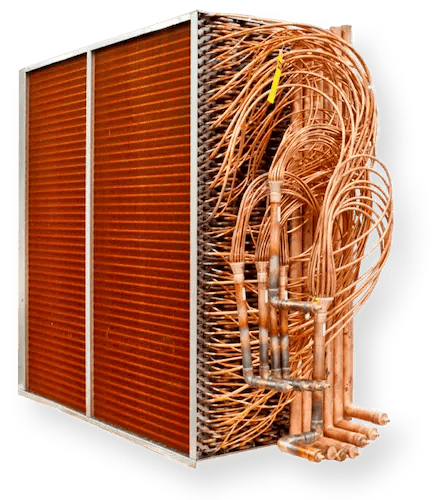

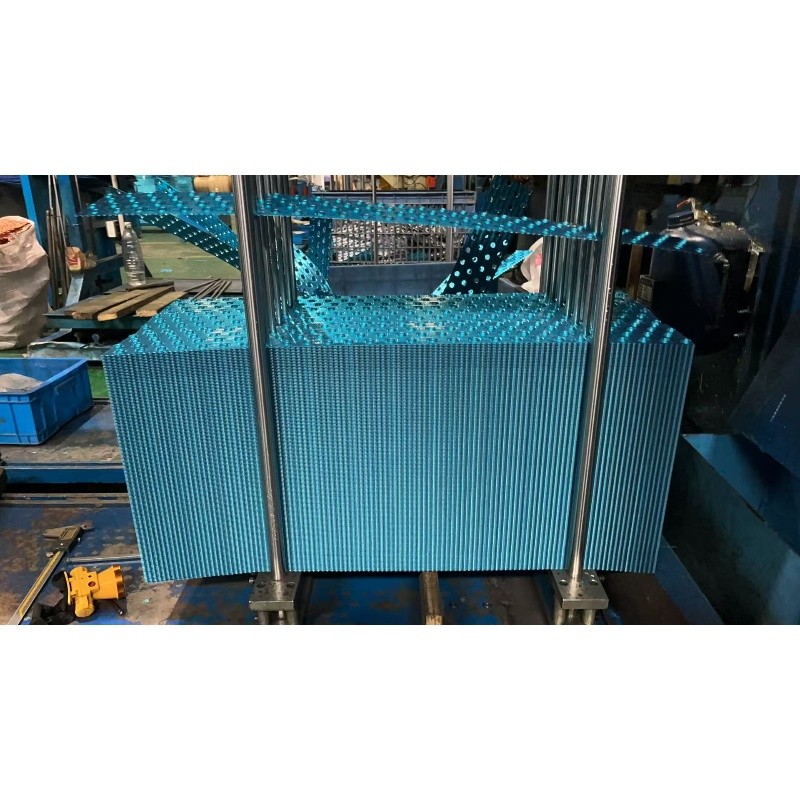

Custom Different Size Evaporator Coil with Copper Tubes Aluminum Fin

| Share | |

|---|---|

| Categories | Evaporator Coils |

| Brand | Boyi Heat Exchanger Custom Manufacturing |

| Model | BY-ZFQ |

| Core Component | Finned Tube Heat Exchanger |

| Tube Diameter | 7mm, 9.52mm, 12.7mm, 15.88mm |

| Casing Material | Galvanized Steel, Aluminium, Stainless Steel |

| Tube Material | Copper, Stainless Steel |

| Fin Material | Aluminum, Copper, Stainless Steel |

| FOB port | guangzhou |

| Terms of Payment | L/C, D/P, Western Union, MoneyGram, T/T, Paypal |

| Update Time | Feb 16,2026 |

Detail Information

Custom Different Size Evaporator Coil with Copper Tubes Aluminum Fin

We're a coil manufacturer and heat exchangers manufacturer and among our specialties are evaporator coils to suit any needs. Evaporator coils are a crucial part of any refrigeration system, which is why every evaporator coils we build each year is fully tested to ensure it meets your standards.

In a heat pump system, the operation detailed above is reversed with the evaporator coil expelling the heat into the building.

How They Work

1. Refrigerant Flow: Low-pressure liquid refrigerant enters the coil via an expansion valve, which regulates the flow.

2. Heat Absorption: As warm air passes over the coils, the refrigerant absorbs heat, causing it to evaporate into a gas.

3. Cool Air Circulation: The now-cooled air is blown into the living space (in ACs) or cools the refrigerator compartment.

4. Cycle Continuation: The gaseous refrigerant travels to the compressor to restart the cycle.

Materials for Construction

1. Aluminum fin

2. Hydrophilic pre-coated aluminum fin

3. Copper tube and fin

4. 304/316 Stainless Steel

5. Epoxy resin coatings

Refrigerant Experience

1. Pure refrigerants such as R134a, R32 and R1234ze.

2. Refrigerant mixtures including R410A, R407C, R438A, R-454B, and R452A.

3. Supercritical refrigerant CO2.

4. Natural refrigerants such as Propane, Isobutane and Ammonia.

Maintenance & Common Issues

1. Dirt/Dust Buildup: Reduces efficiency; clean coils annually with a soft brush or coil cleaner.

2. Ice Formation: Caused by low refrigerant, poor airflow, or faulty components. Address promptly to prevent damage.

3. Refrigerant Leaks: Lead to poor cooling; require professional repair.

4. Bent Fins: Restrict airflow; gently straighten with a fin comb.

Conclusion

Our evaporator coils are used in several industries, including gas compression, HVAC, military, transit cooling, refrigerated display cases, data center electronics cooling, and ground support.

- Specifications can be tailored to suit each application, with different materials, sizes, noises and cooling mediums available.

- contact us

Review

- Loading...

Contact Us to Obtain Your Design Proposal Now!

Whether you are a brand owner, OEM manufacturer, engineering company, or end user, as long as you have cooling needs, Boyi Cooling can provide you with technically feasible and cost-effective solutions.

- *Name

- *Phone

- *Title

- *Content