Innovative Commercial and Industrial Heat Transfer Solution Providers

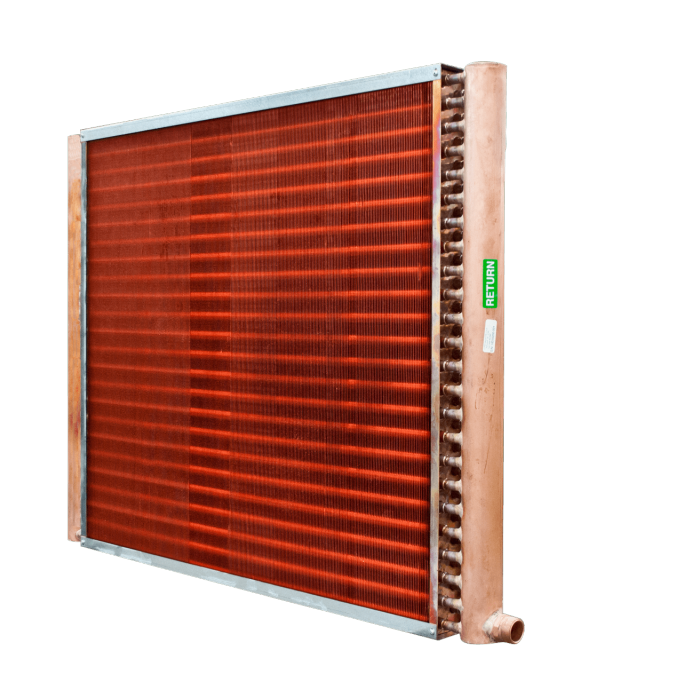

Custom Steam Coils with different materials

| Categories | Heating & Cooling Coils |

|---|---|

| Brand | Boyi Heat transfer industry support customization |

| Model | BY-ZQPG |

| Core Component | Finned tube heat exchangers |

| Tube Diameter | 7mm, 9.52mm, 12.7mm, 15.88mm |

| Casing Material | Galvanized Steel, Aluminium, Stainless Steel |

| Tube Material | copper, stainless steel |

| Fin Material | aluminum, copper, stainless steel |

| FOB port | guangzhou |

| Terms of Payment | L/C, D/P, Western Union, MoneyGram, T/T, Paypal |

| Update Time | Jul 1,2025 |

Detail Information

Definition:

Steam coils are designed and manufactured for applications ranging from commercial to industrial. Their primary function is to heat the air when steam is available.

Typically, these coils are built with thicker materials due to steam temperature/pressures, added chemicals, dissolved air in the steam and/or the high velocity of steam travelling through tube openings.

In order to get the most out of the steam coil design, all condensate must be removed. This can be achieved through a pitched design and/or ensuring that the steam has sufficient velocity. Without removal, users can expect decreased thermal performance or experience water hammer-type effects or coil failure.

Features of Construction:

1. Opposite or same end connections

2. Pitched casing for proper condensate removal

3. Enclosed header construction

4. Thin wall tubing for low steam pressures (5 - 15 psig) to heavier wall tube for higher pressure steam (150+ psig)

Materials:

1. Aluminum fin

2. Hydrophilic pre-coated aluminum fin

3. Copper tube and fin

4. 304/316 Stainless Steel tube and fin

5. Epoxy resin coatings

Maintenance & Common Issues:

1. Dirt/Dust Buildup: Reduces efficiency; clean coils annually with a soft brush or coil cleaner.

2. Ice Formation: Caused by low refrigerant, poor airflow, or faulty components. Address promptly to prevent damage.

3. Refrigerant Leaks: Lead to poor cooling; require professional repair.

4. Bent Fins: Restrict airflow; gently straighten with a fin comb.

Conclusion:

Steam coils are widely used in commercial, industrial, and residential heating systems due to their reliability and energy efficiency. No matter what your need, we can custom design an steam coils for you. Get started with BOYI Coils as your HVAC coils manufacturer today!

- Specifications can be tailored to suit each application, with different materials, sizes, noises and cooling mediums available.

- contact us

Review

- Loading...

Related Products

Please send your message to us

- Tel

- *Title

- *Content