Innovative Commercial and Industrial Heat Transfer Solution Providers

Home / All / Dry Coolers /

With relatively high coolant temperature and favorable climate condition, dry coolers are fully utilized as a natural cooling system

With relatively high coolant temperature and favorable climate condition, dry coolers are fully utilized as a natural cooling system

Detail Information

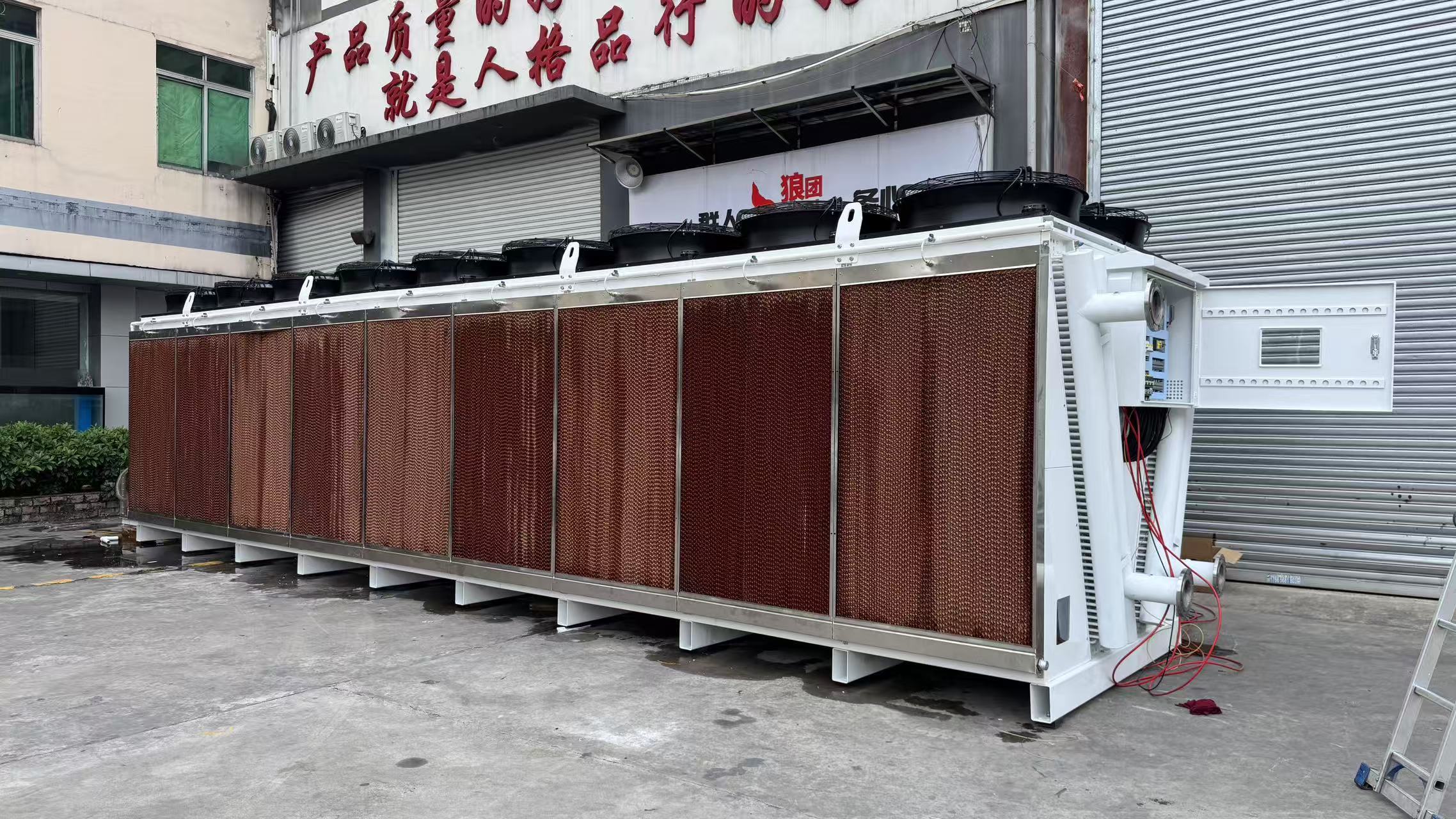

V-Type Dry Cooler Key Features:

1. V-Type design for easy installation and space-saving.

2. Efficient heat dissipation to prevent equipment overheating.

3. Specifically designed for industrial cooling systems in data centers.

4. Reliable and durable construction for long-lasting performance.

Background:

In liquid-cooled data centers, if the coolant temperature is relatively high (e.g., with a designed supply temperature of 35–45°C), and the local climate conditions are favorable (such as low annual average temperature, significant day-night temperature variations, or dry air), dry coolers can completely replace traditional mechanical refrigeration systems, enabling 100% year-round free cooling operation. This solution offers significant advantages in energy savings, water conservation, and cost reduction. However, its feasibility depends on precise alignment between system design and environmental conditions. Below is a detailed analysis and practical implementation strategy.

The adaptation logic of high water temperature and natural cooling:

The core advantage of liquid cooling systems lies in their ability to operate at higher coolant temperatures (compared to the 7-12°C supply water temperature of traditional chiller units), thereby significantly improving the utilization of free cooling. For example:

1. High-temperature liquid cooling design:

Set the supply coolant temperature to 40°C and the return temperature to 45°C. In this case, the dry cooler only needs to cool the 45°C liquid down to 40°C for recycling.

2. The environmental temperature threshold has been widened:

Assuming the minimum effective temperature difference (between the coolant and the air) of the dry cooler is 5°C, the dry cooler can operate when the air temperature is ≤40°C. If the air temperature is ≤35°C, efficient heat dissipation can be achieved. Compared to traditional chillers, the applicable temperature range of the dry cooler is extended by over 20°C.

3. Case:

A data center in Norway utilizes a liquid cooling system with a supply temperature of 45°C. Combined with the local annual average temperature of 7°C, the dry cooler achieves a natural cooling utilization rate of 98% year-round, resulting in an ultra-low PUE of 1.08.

Key assessment dimensions of climatic conditions:

The natural cooling system relying entirely on dry coolers must meet the following climatic characteristics:

1. The low temperature lasts for a long time:

The annual cumulative time with temperatures below the design upper limit of the dry cooler (e.g., 35°C) accounts for over 95% of the total time.

2. Air Dryness:

In regions with low relative humidity (e.g., <60%), dry coolers exhibit higher sensible heat exchange efficiency; in high-humidity areas, they need to be combined with wet pads or spray systems.

3. The air quality is excellent:

The PM2.5 concentration should be kept below 50 μg/m³ to prevent fouling of the fins, which can lead to increased thermal resistance.

4. Typical applicable regions:

4.1 Temperate continental climate: Such as in North China and the North American Great Lakes region, where winters are cold and summers are mild.

4.2 Alpine climate: Such as the Yunnan-Guizhou Plateau and the Swiss Alps region, where the daily temperature variation is large and the air is clean.

4.3 Drought desert climate: In regions such as the Middle East and North Africa, although daytime temperatures are high, the nighttime radiative cooling effect is significant, making them suitable for integration with phase-change cold storage systems.

System design optimization strategies:

1. Selection and layout of dry coolers:

Increase the heat exchange area: Utilize a multi-row finned tube (4-6 rows) design to compensate for the reduced temperature difference caused by high water temperature.

1.1 Variable frequency fan control: Adjusts fan speed based on real-time load and temperature to reduce energy consumption under partial load conditions.

1.2 Distributed deployment: Scatter the dry cooler modules around the periphery of the data center to enhance convection by utilizing natural wind.

2. The parameter optimization of liquid cooling systems:

2.1 Increase the coolant temperature: Within the chip's temperature tolerance range (e.g., Intel CPU's maximum junction temperature of 100°C), raise the coolant temperature to 40-50°C to expand the natural cooling window.

2.2 Flow dynamic adjustment: The intelligent valve controls the cooling fluid flow to match IT load fluctuations, preventing excessive heat dissipation.

3. Climate resilience enhanced:

3.1 Nighttime cold storage compensation: During low-temperature nights, excess heat dissipation from dry cooler is utilized to store energy in cold storage tanks (such as ice storage or phase-change materials), which then release cooling capacity during the day to cope with short-term high temperatures.

3.2 Dry-wet hybrid mode: During periods of extreme high temperatures in summer, briefly activate the wet curtain or spray system to reduce the air inlet temperature by 3-5°C, ensuring the continuous operation of the dry cooler.

Economic Benefits and Risk Control:

1. Cost-benefit analysis:

1.1 Energy saving: After phasing out compressors and cooling towers, the energy consumption of the refrigeration system is reduced by 70%-90%.

1.2 Water saving: With WUE maintained at zero, the annual water savings per cabinet can reach 50 tons compared to traditional water cooling systems.

1.3 Investment Payback Period: The initial investment increases by 15%-20% (for expanding the capacity of dry coolers), but operating costs decrease by 40%-60%, typically allowing the incremental costs to be recovered within 3-5 years.

2. Risk mitigation measures:

Redundancy design: Reserve 10%-15% of dry cooler capacity margin to cope with extreme weather or sudden load surges.

2.1 Meteorological Data Linkage: Integrate with the local weather forecasting system to predict high-temperature risks 72 hours in advance, triggering ice storage or wet curtain backup.

2.2 Regular maintenance: Clean the fins and replace the filter every quarter to prevent dust accumulation and corrosion.

Practical Case: A Zero Water Consumption Data Center in Qinghai, China

The design of a certain supercomputing center in Qinghai, located in the Qaidam Basin (with an average annual temperature of 4°C and annual precipitation <100 mm), incorporates the following features:

1. Liquid cooling system: 50°C supply liquid temperature, with cold plates in direct contact with GPU for heat dissipation.

1. Liquid cooling system: 50°C supply liquid temperature, with cold plates in direct contact with GPU for heat dissipation.

2. Configuration of dry cooler: 8 sets of finned tube modules with total heat dissipation capacity of 2MW, paired with phase change cold storage tank (charging at night).

3. The operational results are as follows: 100% natural cooling throughout the year, PUE=1.05, WUE=0, with water-saving benefits equivalent to protecting the ecosystem of a 50,000-square-meter lake annually.

Future Trend: Climate-Driven Data Center Location Selection

With the advancement of dry cooler technology, the location selection of data center is shifting from "close to users" to "close to natural cooling sources." For example:

1. Data centers in the Arctic Circle: Utilizing the -30°C extreme cold air, dry coolers can achieve natural convection heat dissipation without the need for fans.

2. Underwater Data Center: Microsoft's Project Natick has verified the feasibility of combining submerged pods with seawater cooling, while dry coolers could further replace seawater pumping systems.

Conclusion:

When the coolant temperature and climatic conditions form a "high-low temperature" synergistic effect, dry coolers can fully support the natural cooling demands of liquid-cooled data centers, achieving the ultimate heat dissipation goal of zero water consumption and near-zero carbon emissions. This path not only relies on technological innovation but also requires the integration of climate data, load characteristics, and system resilience from the planning stage, thereby redefining the sustainability boundaries of data centers in the "dual-carbon" era.

- Specifications can be tailored to suit each application, with different materials, sizes, noises and cooling mediums available.

- contact us

Review

- Loading...

Related Products

Please send your message to us

- Tel

- *Title

- *Content