Innovative Commercial and Industrial Heat Transfer Solution Providers

Home / All / Dry Coolers /

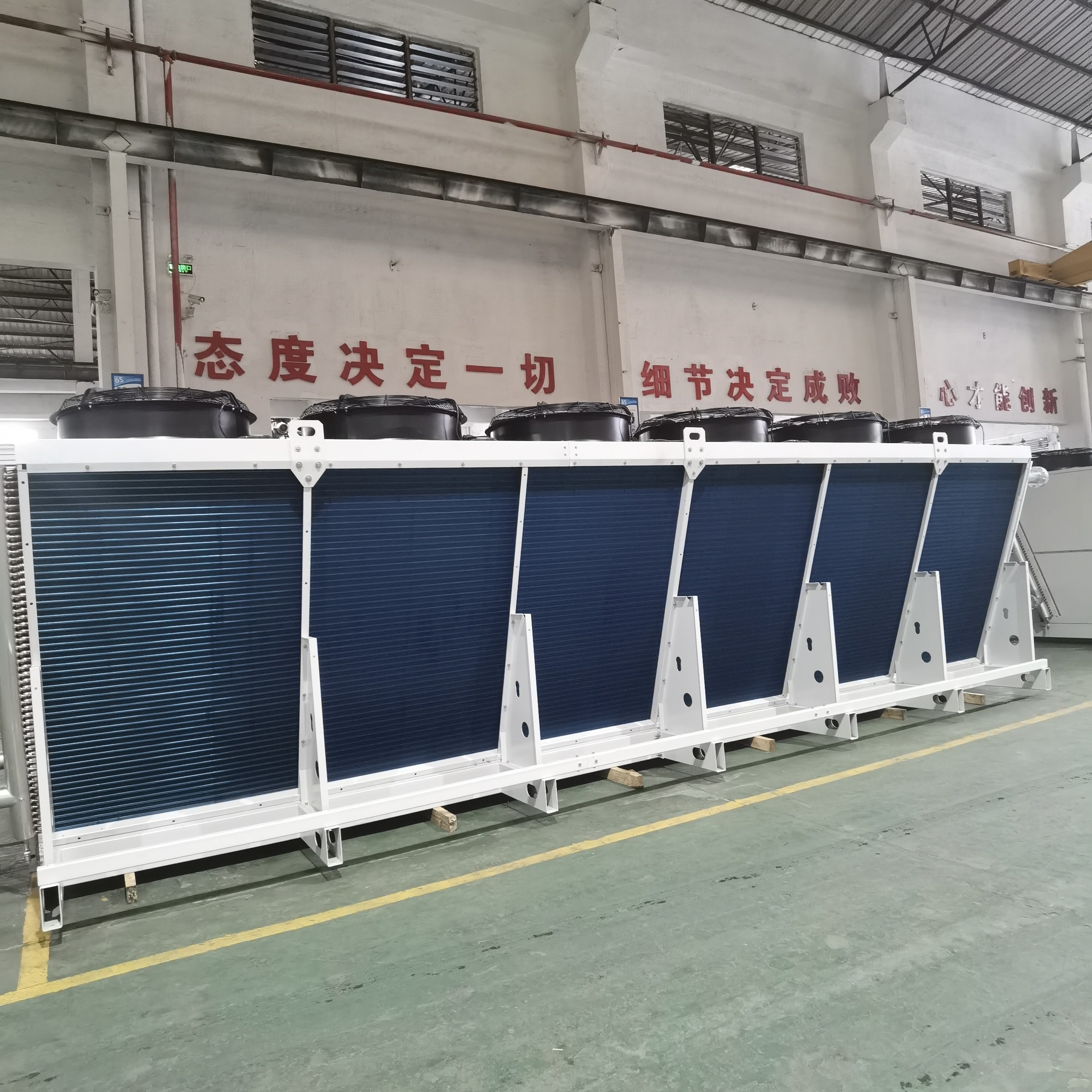

High Efficiency V-Type Dry Cooler with Copper Tube Aluminum Fin for Mining Industry

High Efficiency V-Type Dry Cooler with Copper Tube Aluminum Fin for Mining Industry

Detail Information

V-Type Dry Coolers Key Features:

1. V-Type design for easy installation and space-saving.

2. Efficient heat dissipation to prevent equipment overheating.

3. Specifically designed for industrial cooling systems in the mining industry.

4. Reliable and durable construction for long-lasting performance.

Invest in the BOYI V-Type Dry Cooler for your mining cooling system needs. Experience enhanced cooling efficiency, improved equipment performance, and increased productivity in your mining operations.

V-Type Dry Coolers Product Description:

Dry coolers are mainly for machines cooling, process cooling, oil cooling, free cooling and crypto mining cooling, etc.

For bitcoin server farm, if use immersion cooling system, our dry cooler is the most cost-effective way to remove heat and a necessary component of the immersion cooling system. We designed a full range of immersion optimized dry coolers. From 5kW single fan unit to the V-Type 30KW-2MW dry coolers.

Our range of Dry Air Coolers and Air Blast Radiators are designed for commercial and industrial fluid cooling applications. We offer a wide range of options enabling us to provide the most cost-effective solution for your cooling requirement.

Standard arrangements include flat-bed vertical or horizontal airflow with V and W configurations to offer the smallest footprint.

Whether your application is cooling water / glycol for water cooled chillers, injection moulding machines, furnace equipment, CHP Engine Cooling or any other process. One or more of our units can be selected to give the most cost-effective solution to suit your space and noise requirement.

Energy saving free cooling is possible for most of the year for many applications.

The wetted surface - Adiabatic Cooling option enables water to be cooled to within 6°C of ambient wet bulb, water is used to increase the cooling effect when the ambient dry bulb is 3°C above the design wet bulb - for most of the year the unit operates as a conventional air blast cooler.

Features:

1. High efficiency heat exchangers: Our capacity designs maximize heat transfer while minimizing energy consumption.

2. Low pressure drop: The tube and tube coupling design ensures minimal pressure drop in the coil, providing efficient cooling.

3. Low specific energy consumption fans: Our carefully selected fans offer maximum air flow and air throw, ensuring effective cooling.

4. Durable and reliable: With a protective enclosure, rigid construction, and leakage testing at 31bar, our dry cooler is built to last.

Options:

1. Coils design refrigerant: Choose from water, oil, or glycol.

2. Multiple circuits: Customized the dry cooler to meet your specific cooling requirements.

3. Sub-cooling circuits: Enhance cooling efficiency with sub-cooling capabilities.

4. Material options: Select from stainless steel or aluminum casing for durability.

5. Fin options: Choose between coated aluminum or copper fins for optimal heat transfer.

6. Explosion-proof motor: Ensure safety in hazardous environments.

7. Customized fin spacing: Tailor the dry cooler to your unique needs.

Our mission:

Choose our dry coolers for efficient and reliable cooling solutions. Experience the benefits of our advanced technology and enjoy peace of mind knowing your equipment and environment are protected.

Our mission is to research and develop high-efficiency freezing equipments unceasingly, committing to better serve the product application market.

- Specifications can be tailored to suit each application, with different materials, sizes, noises and cooling mediums available.

- contact us

Review

- Loading...

Related Products

Please send your message to us

- Tel

- *Title

- *Content